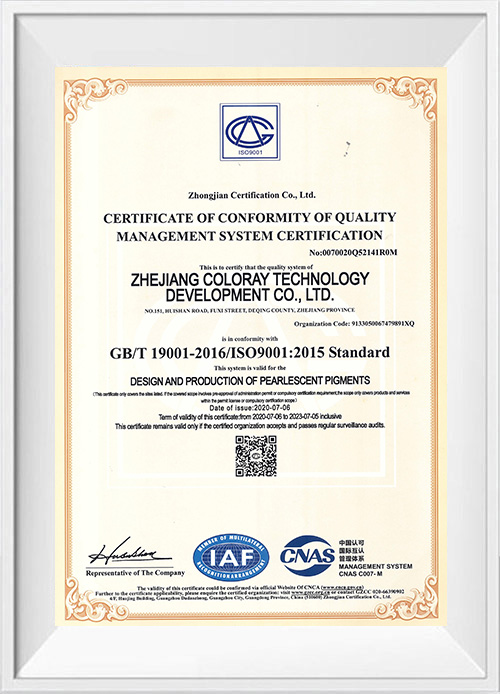

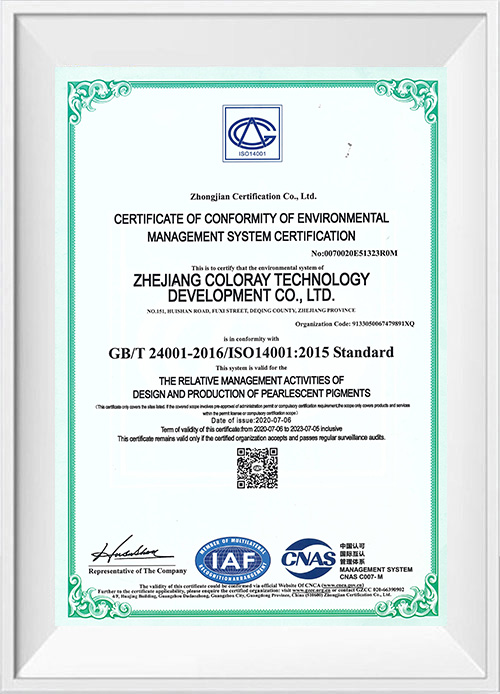

Zhejiang Coloray Technology Development Co., Ltd. is reliable supplier and factory company, it was founded in 2008, focusing on the research and development of cosmetic grade effect pigment for more than 10 years, The company has won many awards, including high-tech enterprise, provincial science and technology enterprise, provincial research and development center, provincial intelligent factory, etc. In 2017, the company was listed on KOSDAQ (stock Código: 900310).

A empresa está localizada no parque industrial nacional de alta tecnologia-Deqing Moganshan High-Tech Zone. No círculo central da zona econômica do Delta do Rio Yangtze, que é uma cidade agradável com uma localização geográfica e um belo ambiente natural, uma vez selecionado pelo New York Times como o décimo oitavo lugar do mundo que vale a pena visitar. A fábrica de Coloray está localizada na pitoresca zona de alta tecnologia de Moganshan em Deqing, onde estamos fazendo cores bonitas.

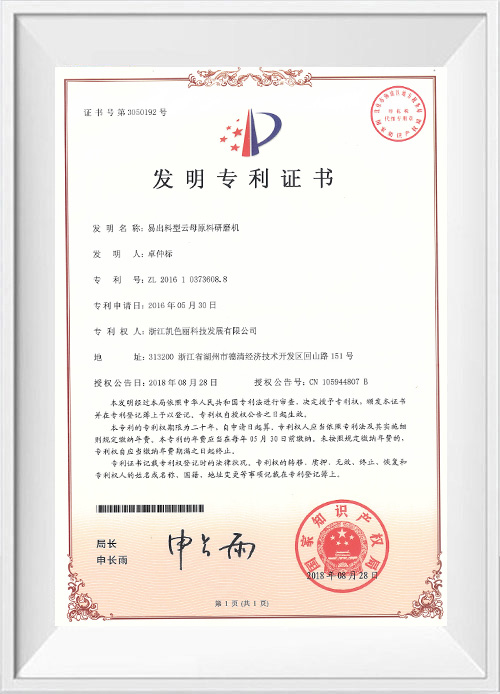

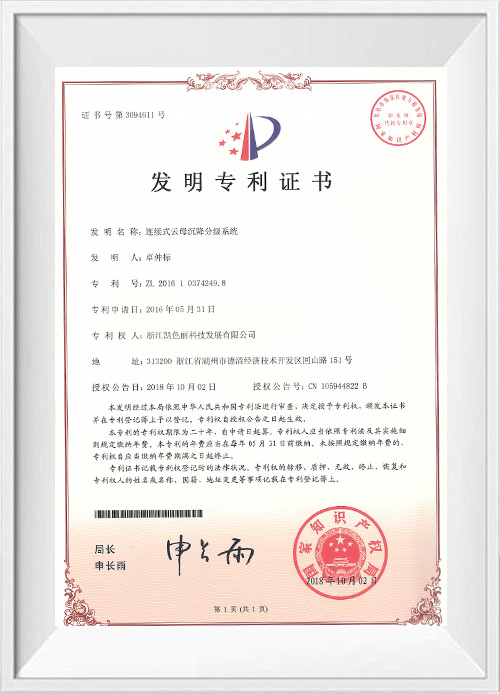

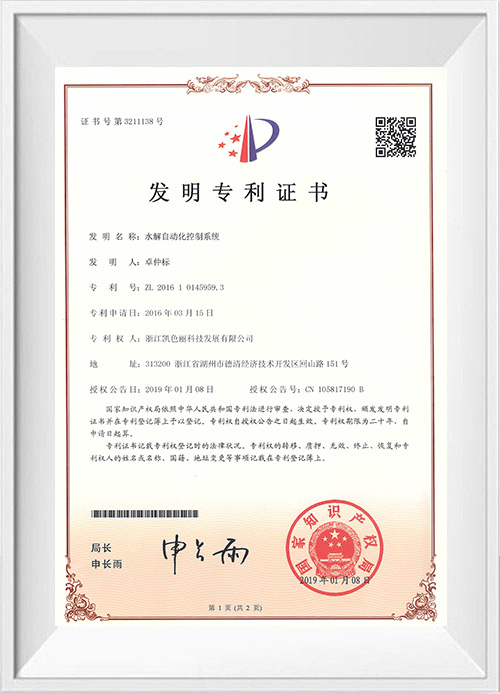

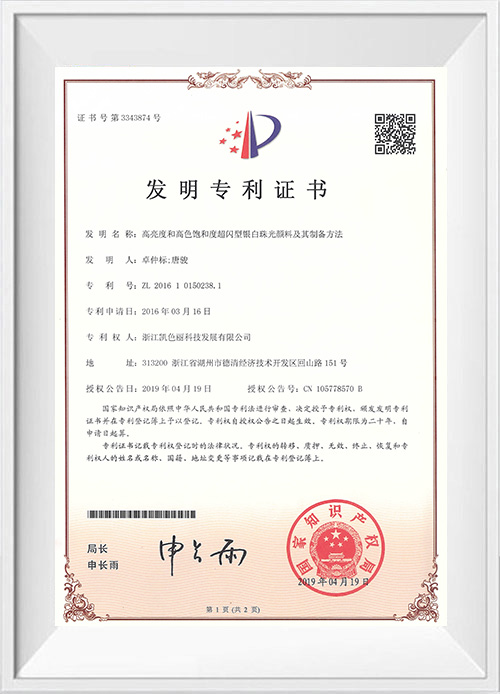

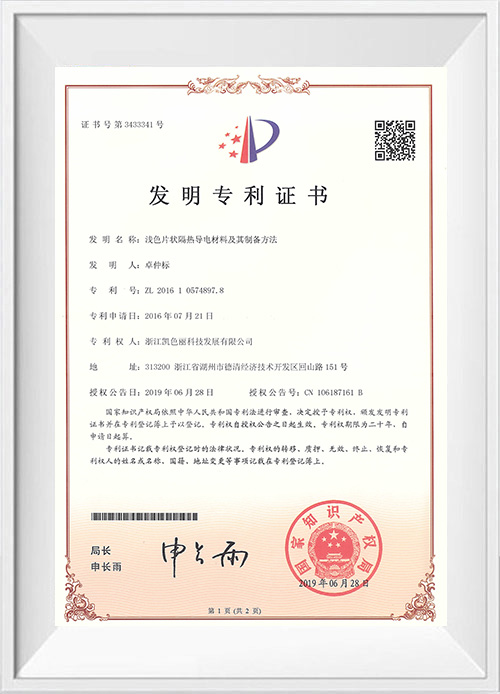

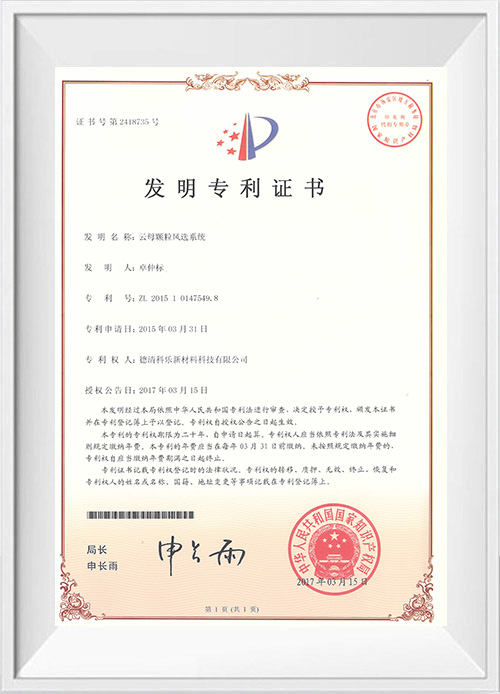

Ao mesmo tempo, a empresa adere ao conceito de inovação, e a inovação tecnológica é uma força motriz inesgotável para as empresas. A empresa desenvolveu cumulativamente mais de mil tipos de produtos de grau cosmético. Para melhorar continuamente sua capacidade de P&D e capacidade de inovação, a Companhia estabeleceu a cooperação da pesquisa-academia da indústria com as principais universidades e introduziu um grande número de talentos de alto nível nacional e estrangeiro.

O COLORAY está comprometido em fornecer aos usuários de cores uma variedade de pigmentos de efeitos com excelente desempenho, estabilidade e consistência em lote; Tenha suporte técnico profissional e competitividade de preços. Sejam cosméticos, revestimentos, plásticos, tintas de impressão, couro ou a indústria da construção, a Coloray é um fornecedor e parceiro de longo prazo de muitas marcas internacionais, garantindo uma qualidade consistente e resultados únicos. Seja selecionando um produto atual em nosso manual de produtos ou buscando um serviço personalizado, entre em contato conosco. Nossa equipe experiente fará o possível para atender às suas necessidades e satisfazê -lo. Com qualidade, forte suporte técnico e serviços abrangentes, a Coloray é seu parceiro.

- Lar

- Sobre

- Produtos

- Pesquisa condicional

- Pigmento perolado de grau cosmético

- Pigmentos de mudança de cor

- Novo pigmento perolado colorido

- Pigmento perolado magenta

- Açafrão Pigmento Pearlescente

- Pigmento perolado de ouro cúpula

- Pigmento perolado de platina

- Pigmento pearlescente de pele nua

- Pigmento perolado de alto Chroma

- Star Diamond Pearlescent Pigmment

- Scintillance Pigment Pearlescent

- Pigmento peroloso antigo

- Pigmentos de pérolas com revestimento de prata de Rayshine

- Pigmento perolado de lava

- Pigmento perolável natural

- Pigmento de Crystal Pearlescent

- Diamond Pearlescent Pigment

- Pigmento perolado revestido a cores

- Pigmento perolado livre de TiO2

- Raysoft Silicone revestido de pigmento perolado

- Tratamento superficial pigmento perolado

- Pigmento Pearlescente Magnético Ray-3d

- Pigmento perolado de grau industrial

- Revestimentos automotivos

- Novo produto

- Aplicativo

- Apoiar

- Notícias

- Contato